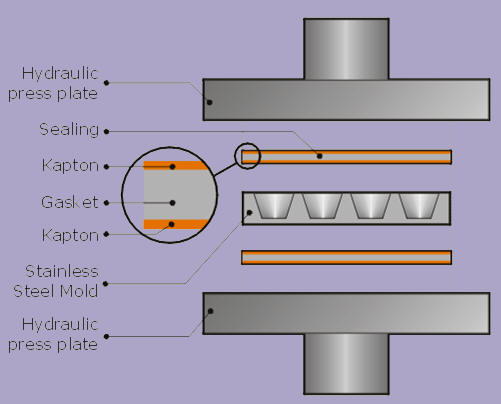

Using the rapid supercritical extraction technique, the aerogel precursors are poured into each cup of a steel mold. The Mold is then sandwiched between layers of Kapton polyimide high temperature film and a gasket sealing material. These layers are then compressed by the hydraulic press plates on either side of the mold. When the temperature of the press plates rises, the temperature and pressure of the liquid in the mold rises rapidly to supercritical conditions due to the constant volume thermodynamic properties of the mold. Once the sol-gel mixture is at supercritical conditions, the force of the press is slowly lowered and the supercritical fluids escape, leaving behind an aerogel.

Using the rapid supercritical extraction technique, the aerogel precursors are poured into each cup of a steel mold. The Mold is then sandwiched between layers of Kapton polyimide high temperature film and a gasket sealing material. These layers are then compressed by the hydraulic press plates on either side of the mold. When the temperature of the press plates rises, the temperature and pressure of the liquid in the mold rises rapidly to supercritical conditions due to the constant volume thermodynamic properties of the mold. Once the sol-gel mixture is at supercritical conditions, the force of the press is slowly lowered and the supercritical fluids escape, leaving behind an aerogel.