About the Make Lab

The Make Lab is and interdisciplinary space open to all students and faculty from all departments. The Lab is a space for making and building and can be used for coursework, research, or just to tinker and learn new tools. The Lab has recently been renovated and is located in Room 107 of the Machine Shop (commonly referred to as the Student Machine Shop). The Lab houses a new CNC metal milling machine for student use and is equipped with a host of metal and wood working tools of various scales and both digital and analog. While the Lab is somewhat focused on machining and metal work, we offer a broad range of equipment, electric and hand tools to support your creativity. A full list of the tools and equipment is below which includes 3D printers, vacuum forming machines, welding equipment and much more! The Lab is staffed with Maker Web work students who can assist you, guide your creativity, and help you use tools and equipment. Please see the Maker Web student schedule below. If you have any questions about how to access the Lab or about our resources please feel free to stop by the Lab during our staffed hours or submit an inquiry below.

We look forward to seeing you in the Lab and helping you to MAKE your design ideas become realities!

HOW CAN WE HELP YOU?

![]() CLICK HERE TO SUBMIT AN INQUIRY

CLICK HERE TO SUBMIT AN INQUIRY

MAKE LAB SPRING 2022 SCHEDULE

Getting to know the Resources

The Make Lab hosts a wide array of tools and equipment and allows for a wide range of material output. Some resources require our certification prior to use but most of the tools can just be used freely and the Maker Web staff can assist you learning and using all of the tools. From cutting edge CNC technology and 3D Printing to traditional hand and electric tools, the Lab offers a lot of opportunities to explore making things at a variety of scales and from a variety of materials. Please have a look at the list of tools and equipment and stop by the Lab to explore and use the resources. The Lab is open to anyone in the campus community and we are here to assist you.

SEE OUR FULL LIST OF TOOLS AND EQUIPMENT (updated regularly)

SEE OUR FULL LIST OF TOOLS AND EQUIPMENT (updated regularly)

Getting Certified to use the Bridgeport Milling Machine and the Metal Lathe

Students and Faculty can now get certified to use the Make Lab’s Milling Machine and Lathe during our staffed hours. No prior knowledge or experience is necessary and the certification process is made for beginners! Click on the link below to schedule your visit. Please remember to bring safety goggles. The hands-on sessions are one on one with a Lab employee and take about an hour. Please review the appropriate certification tutorial PDFs below before your visit. Keep in mind that the two machines have their own specific certification. In order to use both machines you have to be certified on both and will need to make two appointments. Note that the Mill and Lathe can ONLY be accessed by certified users during our open hours under the supervision of a Maker Lab employee.

![]() SIGN UP FOR A CERTIFICATION APPOINTMENT

SIGN UP FOR A CERTIFICATION APPOINTMENT

Review the Bridgeport Milling Certification Tutorial

Review the Metal Lathe Certification Tutorial

Use our 3D Printers to Bring Your Designs to Life and Harness the Power of Rapid Prototyping

While you can submit and receive 3D prints through our 3D Printing Lab, it is now also possible to use the Make Lab printers on your own if you want to learn more about the process and work hands-on with a machine. The Make Lab hosts two (user friendly) Flash Forge Adventurer 3 3D Printers for student and faculty use. The machines are made for beginners and are very easy to use. No prior knowledge is necessary and training materials are located in the Lab so that the machines are ready to be used by anyone regardless of experience level. We have the software and the hardware you need to get stated so come try it out! See the links below to learn more about the machines and the software used to create the 3D print files.

3D Printing Links

GETTING STARTED WITH THE ADVENTURER 3D PRINTER

FREE 3D MODEL LIBRARY FOR DOWNLOAD

Leverage the Power of Advanced Digital Fabrication by Learning the Software and Submitting Your Own CNC Milling Files.

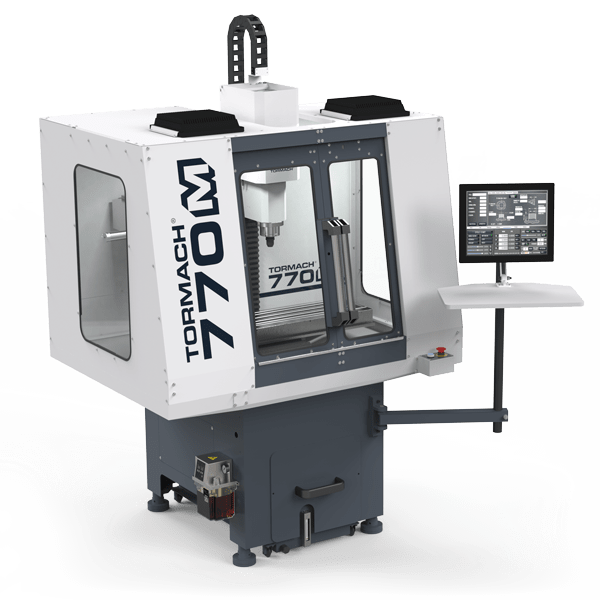

Students and Faculty will soon be able to submit files to our new Tormach 770M CNC (Computer Numerically Controlled) Milling Machine. This is a 3 Axis subtractive manufacturing machine for cutting and carving metal that is capable of making incredibly complex and precise objects. This cutting edge machine puts advanced manufacturing processes in the palm of your hand and our upcoming Certification Process will allow you to learn about manufacturing constraints and opportunities and real life digital to physical workflows. Once you are certified you are able to submit your designs to our staff anytime and they will show you how the machine works as they make your part come to life. See the links below to learn more about the machine and its capabilities. Stay tuned for more details or submit an inquiry to learn more about the new machine and how you can use it.

Other Helpful Resources and Links

Introduction to Milling and Lathe Operations

Introduction to Geometric Dimensioning and Tolerancing

VIDEO: Squaring stock material on the Bridgeport mill

VIDEO: How to use a Bridgeport and it’s features