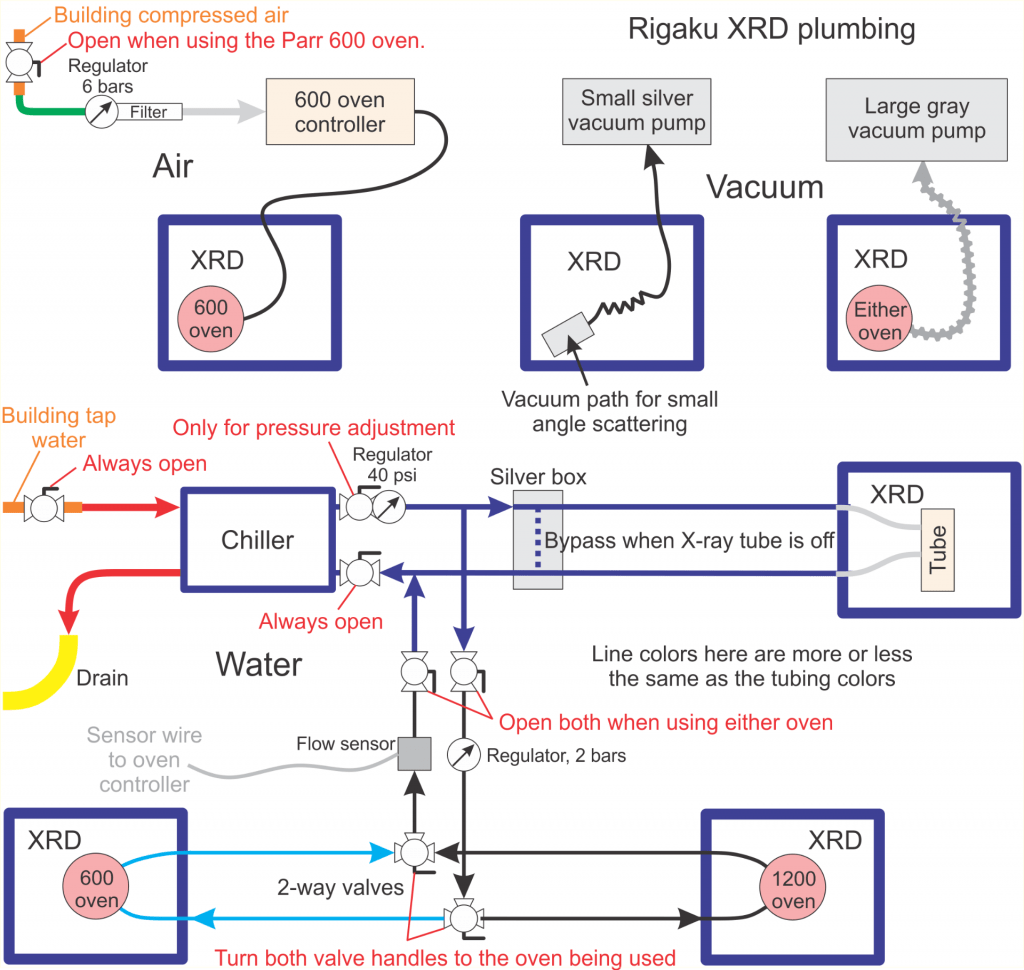

Plumbing schematic for air, vacuum (except turbo pump oven accessory), and water. Compressed air is from a building supply pipe. Water to cool the chiller is from a building tap water pipe. Water to other instrument parts is supplied from the chiller. Here’s a pdf of the schematic.

Line colors on this drawing more or less correspond to hose colors.

Notice that the Parr 600 oven has air and water cooling, whereas the Parr 1200 oven has only water cooling.

The valves numbered 1 to 4 refer to images below.

This is the air supply valve for the Parr 600 oven. It’s the only thing compressed air is used for in the XRD. This valve should be opened only when the Parr 600 oven is being used.

The valve is shown here in its off position.

This is the regulator for the compressed air, which should be regulated to 6 bars. The horizontal cylinder contains a desiccant, which needs to be replaced once in awhile. It comes off using two quick-disconnect fittings at either end. The regulator is built to leak, to automatically purge trapped water. It hisses slightly when the compressed air is on, and briefly hisses a lot when the air is turned on or off.

These yellow valves are on the back of the Haskris chiller. The return valve (right) should always be open, as shown. The supply valve (left) should always be part-way open, to give a pressure reading on the gauge (far left, see below) of 40 psi when the chiller is running. This should rarely need adjustment.

This is the gauge referred to in the image, above. It should read 40 psi when the chiller is running. Adjustment should rarely be necessary.

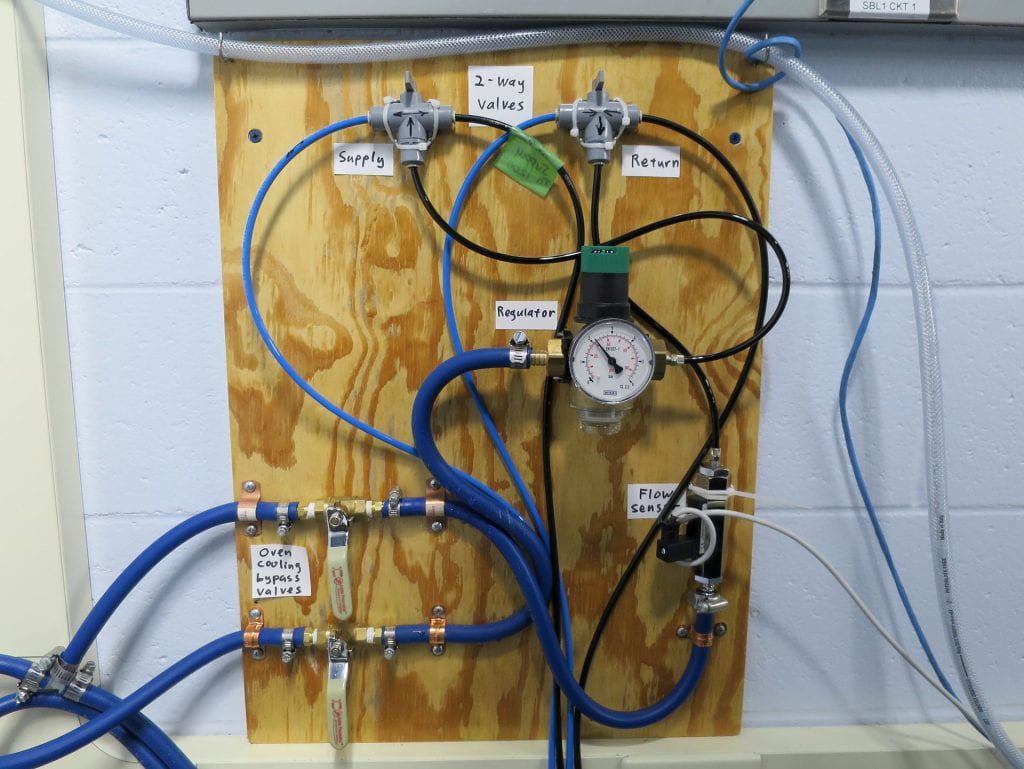

This mess controls cooling water flow to the two ovens. It could be worse, though. How would it be if all this was in a pile on the floor? The two oven water bypass valves, bottom-left, are shown in the closed position. Both must be opened when either of the Parr ovens is operating. Water flows from the bottom valve to the regulator (set to 2 bars), which then flows to the supply 2-way valve. The 2-way valve directs water to either the Parr 600 (left, blue hose), or the Parr 1200 (right, black hose).

The water flows out to the oven and back.

The returning water first goes to the return 2-way valve, which must be set to either the Par 600 (left, blue hose) or Parr 1200 (right, black hose). From the 2-way valve it flows down to the flow sensor, which will turn off the oven (via the controller) if water flow is interrupted. From there, water flows through the second (upper) bypass valve to go back to the chiller.

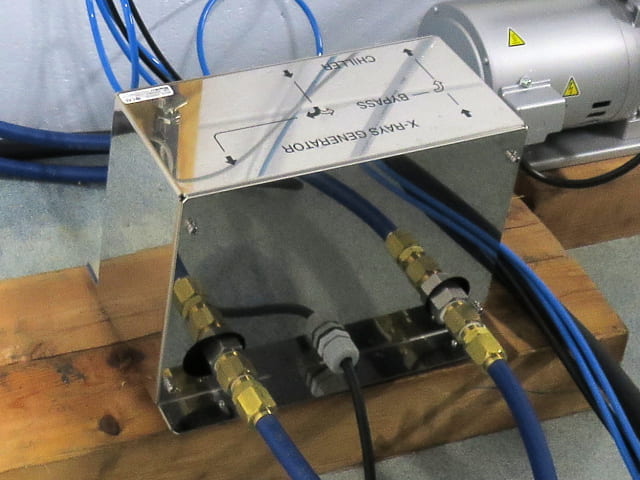

The silver box contains a switch valve that can bypass water flowing to the X-ray tube. When the tube is on, water flows from the chiller through this box, to the tube, back through the box, and back to the chiller. When the tube is turned off but the chiller is still on, the bypass valve directs water from the chiller straight back to the chiller. That prevents condensation around a cold X-ray tube.