We have a Rigaku X-ray diffractometer. This is a complex, computer-controlled instrument that has many different capabilities. It has two X-ray source paths (diverging and parallel beam), a variety of slits and columnators, a regular and two high-temperature heating stages, and a 2-d array solid-state detector. It is equipped with a copper tube rated to 2.2 kW. There are a variety of normal, heated, zero diffraction, capillary, and low-angle sample holders. We also have peak search and match capabilities using NIST and ICDD PDF-2 (2019) powder diffraction file databases.

Instructions and other goodies

A Few Other Things…

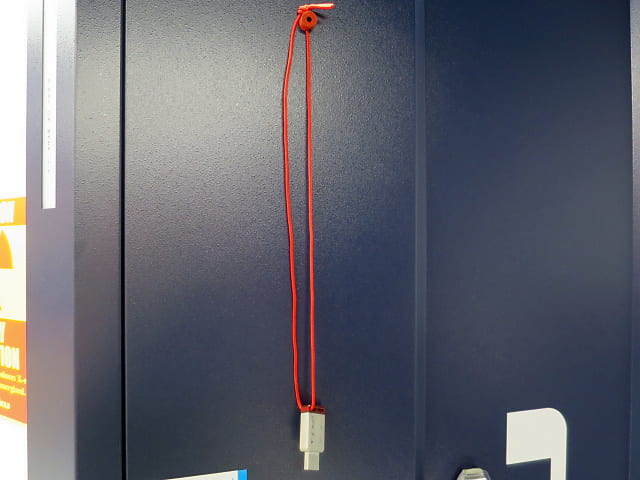

The USB stick, attached by a magnet to the XRD, has help files, manuals, some papers, and other documentation.

One confusing thing in the documentation involves terms used for sample and X-ray spot dimensions. I think this explains what the terms refer to.